ORDER PROCESS

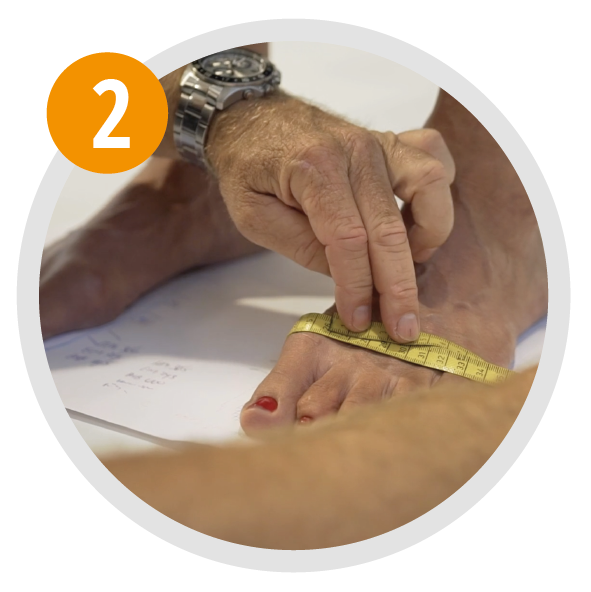

MEASURING

Our orthopedic shoe consultant measures the clients’ feet by making a 3D scan or cast. The foot scans or scan of casts are digitally sent to our CADCAM department.

LASTS AND INLAYS

Our CADCAM team designs the lasts based on the scans of the feet or the sent cast. We mill the lasts and finish them in detail. These lasts are used to make the inlays by hand to the requested measurements and materials. Lasts and inlays are the base of producing all of our orthopedic shoes.

FITTING

The orthopedic shoe consultant can choose to test the lasts and inlays by using a fitting shoe for the client. We call this the fitting phase. After this first fitting phase, a second may follow to test a leather trial shoe or a lining shoe. To make sure the final shoe concept will fit well.

ASSEMBLING THE SHOE

After fitting the trial shoe, the client and the orthopedic shoe consultant sit down together to choose the model that will best meet the clients’ needs. The consultant then enters all the details, such as the closure type, heel height and outsole in our digital order form. All this information is sent to our production facility, along with the marked fitting shoes, lasts and inlays.First, we make the necessary adjustments to the lasts and inlays after which we can start production of the actual orthopedic shoes. When the shoes are made, we will ship them to the orthopedic consultant as agreed.

Deutsch (Deutschland)

Deutsch (Deutschland)

Français (France)

Français (France)

Nederlands (Nederland)

Nederlands (Nederland)